Pilot Plants

PAN Precursor Lab Scale Lines

MAE supplies Complete Lab Scale Turnkey solutions for the production of PAN Precursor 1K tow. Using proven technology by Astris Carbon paired with MAE’s long term industrial experience on PAN precursor processing, we can offer Polymerization and Spinning Packages designed for R&D purposes but already embedding state-of-the- art PAN know-how.

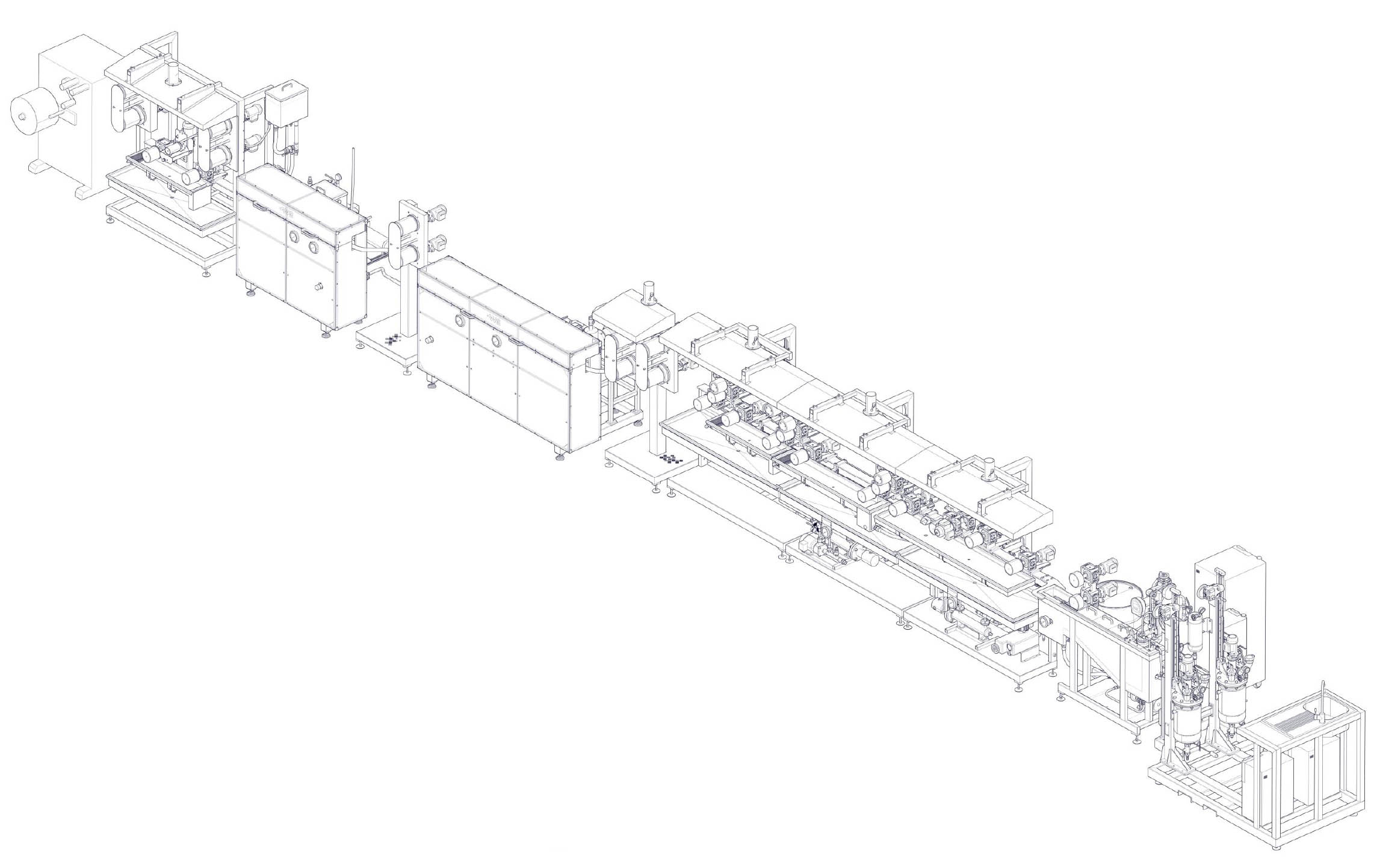

SSOLVE MINI

Solution Spinning Optimized Laboratory Versatile Equipment for chemical fibres spinning

MAE’s industrial experience applied to lab scale

The new laboratory line exploits MAE’s long experience in the design and manufacture of equipment and complete industrial and pilot plants for fibre production by solution spinning.

Such experience allows combining in the same lab line the very strong construction typical of the industrial lines with the great flexibility in changing process condition and component set up required by the research and development work.

Continuous production

Continuous production is possible thanks to a spinning pump; this feature allows R&D teams to work all day long to produce one tow of fibre to be tested and to verify its mechanical properties.

Thanks to a dissolution tank, big enough to feed the spinning line continuously, it is possible to run the lab line for 8 – 10 hours, without any dead times connected to the loading of piston spinning cylinders.

An optional additional dope dissolution tank could extend the working time without stopping the production.

Piston spinning is anyway available for dedicated or special end-uses.

Modularity, Versatility, Flexibility

We offer and develop complete continuous spinning lab lines (as well as pilot lines), which can be customized thanks to a modular concept: this set-up makes it possible to move and reposition our modular units in a few hours, as they are easily movable.

Flexible configuration is the key for lab scale test. We can supply two different arms for Wet Spinning and Air Gap (Dry Jet) Wet Spinning: this feature makes our line ideal for matching R&D purposes, which require the test of different configuration variables each time.

SSOLVE MINI: the perfect solution for R&D purposes

Our flexible line allows managing R&D studies on:

PAN Precursor Pilot Scale Lines

MAE builds Complete Pilot Scale Turnkey solutions for the production of small lots of PAN Precursor to be technically or commercially tested. Using proven technology by Astris Carbon and MAE’s long term industrial experience on PAN precursor processing, we can supply Polymerization and Spinning Packages already designed for a modular scale-up according to state-of-the-art PAN know-how.

Available for different type of fibres

- Acrylic fibres (textile or carbon fibre precursor)

- Aramidic fibres;

- Hollow fibres;

- Regenerated cellulose fibres (viscose, lyocell);

- Fibres from special polymers.

Suitable for a wide range of solvents

- Organic solvents: DMSO/DMAc/DMF;

- Inorganic solvents: NaSCN, ZnCl2, Nitric Acid, Ethylene Chloride, Ethylene Carbonate;

- Acid solvents (Phosphoric acid, Sulphuric acid, …);

- Ionic Liquids.

Suitable for a wide range of solvents

- Dope Preparation Unit;

- Coagulation Bath (Wet Spinning or Air Gap (Dry Jet) Wet Spinning);

- Washing and Drawing Baths;

- Finishing Immersion Bath or Kiss Roll Unit;

- Dryer;

- Laboratory Steam Stretching and Steam Relaxing Machines;

- Winder.

Design Capacities of SSOLVE MINI Laboratory’s Wet Spinning Lines

- Number of tows = 1

- Filament denier range (typical) = 0.5 ÷ 50 dtex

- Winding speed = 20 ÷ 120 m/min

- Production capacity (typical) = 0.1 kg/h up to 0.5 kg/h

- Dissolution tank max capacity = 10 dm3

- Dope solid content (typical) = 10 ÷ 25 % at

- Coagulation bath temperature = -5 ÷ 90 °C

(up to 120 °C special design)

Complete lab line dimensions:

- length (L) = 19 m approx.

- width (W) = 3 m approx.

- height (H) = 2.5 m approx.